The Sado Gold and Silver Mines comprises the Nishimikawa Placer Gold Mine and the Aikawa-Tsurushi Gold and Silver Mine, each of which contain a different type of deposit. Technologies were developed for each of their deposits, with placer gold being mined at Nishimikawa, and gold ore mined at Aikawa-Tsurushi.

In Nishimikawa, an excavation method called “Onagashi” (great flow) was operated to collect placer gold, which was sent to the Magistrate’s Office in Aikawa.

Here, you will learn how works were carried out from ore mining to koban (gold coin) minting in Aikawa.Mining Technology during the Edo Period

1Mining Ore

In the early stages of mining, the principal method of ore extraction was surface mining. It was implemented to obtain exposed ore by extracting vein outcroppings on the surface along with soil and stone around them. The Doyu-no-Warito Opencut Site, a symbol of the Sado Gold and Silver Mine, is a representative example of surface mining.

In surface mining, it is relatively easy to excavate ore near the surface. As miners followed the veins and dug deeper from the surface however, it became difficult to transport ore and drain water. To excavate lode deposits underground while avoiding these issues, tunnel mining was introduced. Tunnels were dug from the side of the mountain toward identified lodes, making ore transportation and drainage easier, and also enabling concurrent excavation of multiple veins.

To dig tunnels horizontally, an advancement was made in surveying techniques. As the tunnels extended deeper, underground water posed a problem. The Archimedean screw (Suisho-rin) was introduced to pump water up efficiently, and the technique of combining timbers to reinforce some parts susceptible to collapse on the tunnel walls was developed.

The miners used pincers to hold a chisel, placed the chisel against the bedrock, and hit the chisel with a hammer. Since uedabashi were used for clamping, even shortened chisels could be used. The ore at the Aikawa Gold and Silver Mines was hard enough that miners were only able to dig ten centimeters a day and one chisel was completely worn out in two days per miner. Grain threshing machines were reformed to be used as ventilators inside the tunnels.

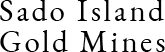

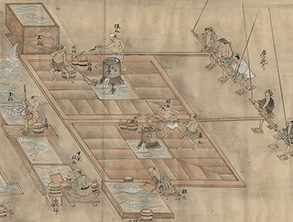

“Sado no kuni kinginzan shikioka kasegikata no zu”

(Drawing of mining on Sado gold and silver mines)

[Collection of The Niigata Prefectural Museum of History]

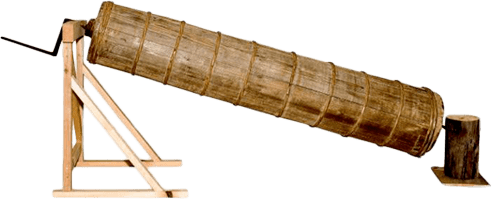

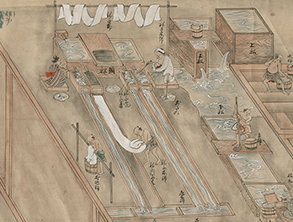

“Sado no kuni kanahori no maki”

(Picture of gold production on Sado)

[Collection of Aikawa Folk Museum]

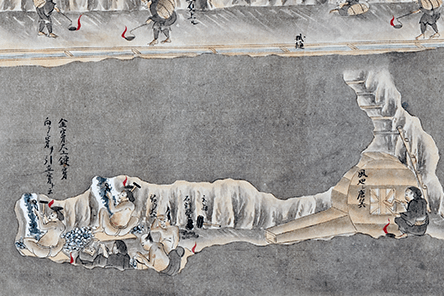

Drainage technology

As mining in a tunnel was a constant battle against water, drainage was the most crucial part of the work. In the old days, supon-doi (water pumps based on the principle of a syringe) were used, but in 1653, suisho-rin (Archimedean screw pumps) were introduced for efficient drainage of water.

Suisho-rin is a water drainage device that draws water up by rotating a cylinder with a spiral plate attached to it and has long been used in the West as the so-called Archimedean screw pump. suisho-rin were introduced to Japan via China during the Edo period.

“Sado no kuni kanahori no maki” (Picture of gold production on Sado)

[Collection of Aikawa Folk Museum]

2Sorting ore(ore-dressing)

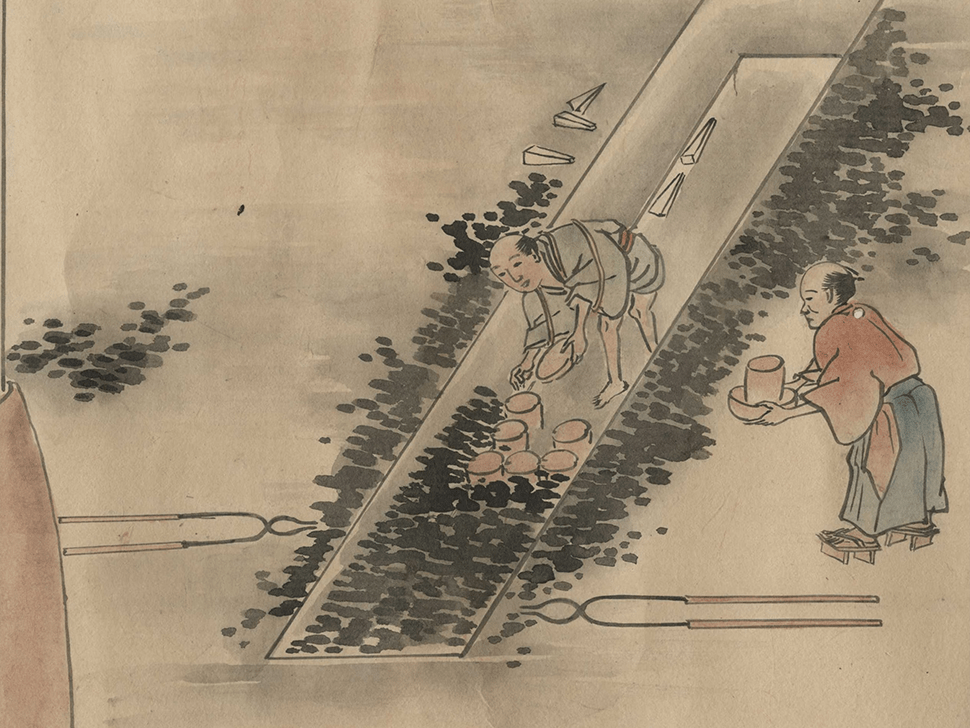

The mined ore was brought to the ore-dressing plant, crushed with an iron hammer, and ground into finer granules with a stone mill. The ore was then placed in a water tub and sifted using a pan to separate the lighter sand from the heavier gold and silver.

The remaining sand, which still contained a small amount of gold and silver, was subjected to a process called neko-nagashi (blanket sluice). A cotton cloth was laid on a wooden frame shaped like a slide with water running, and the sand was poured over the cloth so that the gold and silver contained in the sand would adhere to the cloth. This activity was repeated many times to recover the gold and silver.

The stone mills used in Sado for crushing ore were ingeniously designed for efficiently grinding ore by changing the stone quality of the upper and lower parts of the stone mill. The upper part of the stone mill was made of spherulitic rhyolite from the Fukiage quarry, and the lower part was made of conglomerate from the Katabe-Kanoura quarry and other quarries on the island.

Gold Extraction Process

-

01.Crush ore with iron hammers

01.Crush ore with iron hammers -

02.Grind The crushed ore with stone mills.

02.Grind The crushed ore with stone mills. -

03.Lay a cotton cloth on the gently slanted sluice and pour the ground ore and water over it to collect fine gold and silver that attach to the cloth. (neko-nagashi)

03.Lay a cotton cloth on the gently slanted sluice and pour the ground ore and water over it to collect fine gold and silver that attach to the cloth. (neko-nagashi)

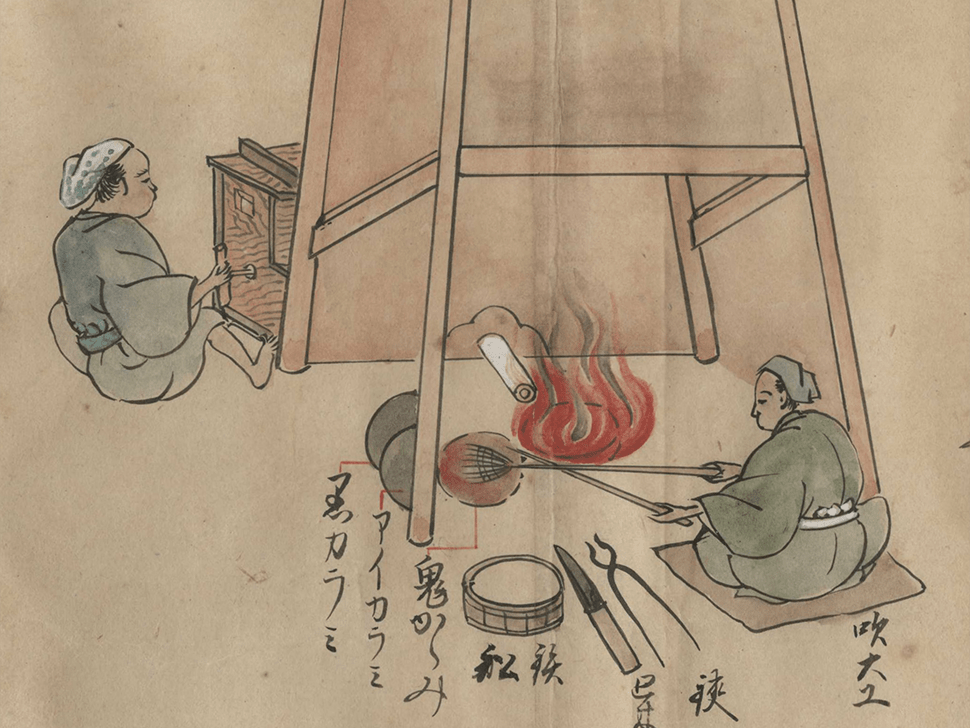

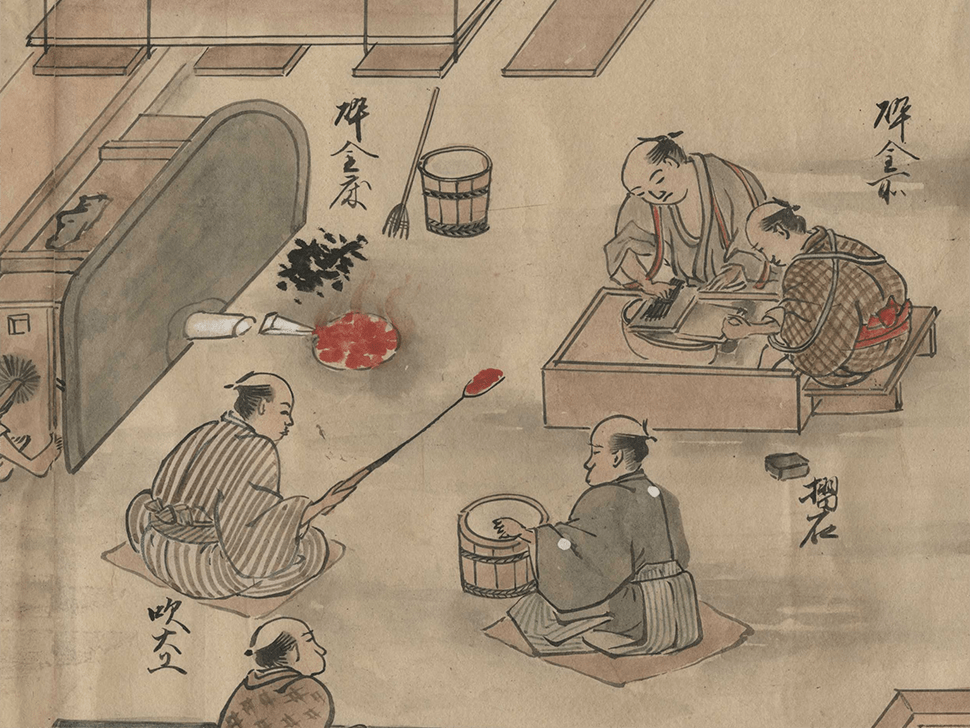

Smelting

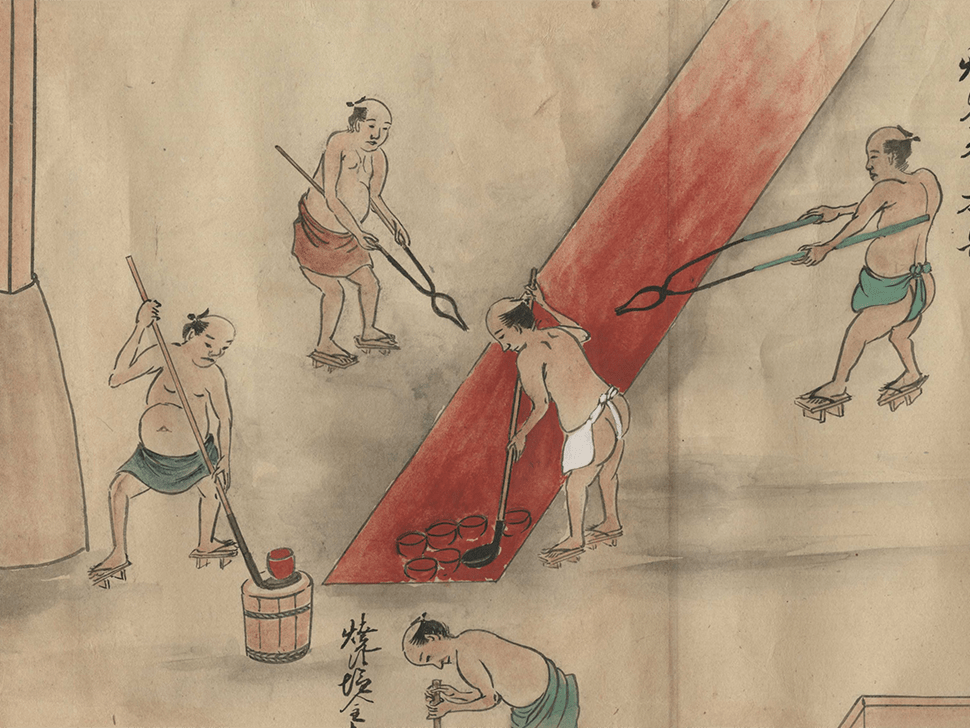

Smelting was done in a place called a tokoya (smelting plant). First, gold and silver recovered at the ore-dressing plant are melted along with lead over a charcoal fire to form an alloy of gold, silver and lead. Next, the alloy is heated in an iron pot covered with ash, and the lead soaks into the ash, leaving only gold and silver. This process is called cupellation, which was introduced from the Iwami Silver Mine. Two methods were used to separate the gold-silver alloy into gold and silver, the “separating silver with sulfur” method, in which sulfur was added, and the “cementation with salt” method, in which common salt was used. These methods were combined and repeated to increase the gold’s purity to match the koban coins’ grade (66-87%)

The remains of furnaces and earthenware excavated in the Sado Magistrate’s Office site as well as historical records including technical books for work procedures and picture scrolls reveal how works were operated at the time. Sado is the only place in Japan and one of the few in the world where remains of the salt cementation technique have been found.

A distinctive feature of the Magistrate’s Office is that the ore-dressing plant and the smelting plant were operated on its premises. Before it was established, ore-dressing and smelting workshops were scattered all over Aikawa. However, due to a decline in output and for the purpose of enhancing efficiency of production management and implementing more careful process management, magistrate Ishigaya Kiyomasa integrated the workshops into the ore-dressing and smelting plants in the Sado Magistrate’s Office in 1759. Thereafter, gold was produced under the direct management and control of the Magistrate’s Office.

Smelting Process

-

01.Add lead to the sand-like ore containing gold and silver, obtained in the ore-dressing process. This process removes impurities and produces a gold-silver-lead alloy (work lead).

01.Add lead to the sand-like ore containing gold and silver, obtained in the ore-dressing process. This process removes impurities and produces a gold-silver-lead alloy (work lead). -

02.Spread ash over the iron pan, place the work lead on top, and heat it. The lead melts first and absorbed by the ash, and gold and silver remain.

02.Spread ash over the iron pan, place the work lead on top, and heat it. The lead melts first and absorbed by the ash, and gold and silver remain. -

03.Finely crush the gold-silver alloy obtained from the previous step.

03.Finely crush the gold-silver alloy obtained from the previous step. -

04.Mix the finely crushed alloy with salt and stiffen it into a cylindrical shape.

04.Mix the finely crushed alloy with salt and stiffen it into a cylindrical shape. -

05.Place cylindrical electrum between earthenware pots, arrange them in a furnace, and fill charcoal around them.

05.Place cylindrical electrum between earthenware pots, arrange them in a furnace, and fill charcoal around them. -

06.After heating for a long time, the silver reacts with the salt to form silver chloride, which separates from the gold.

06.After heating for a long time, the silver reacts with the salt to form silver chloride, which separates from the gold.

Photograph (right): Trace of the furnace for cementation at the Sado Magistrate Office -

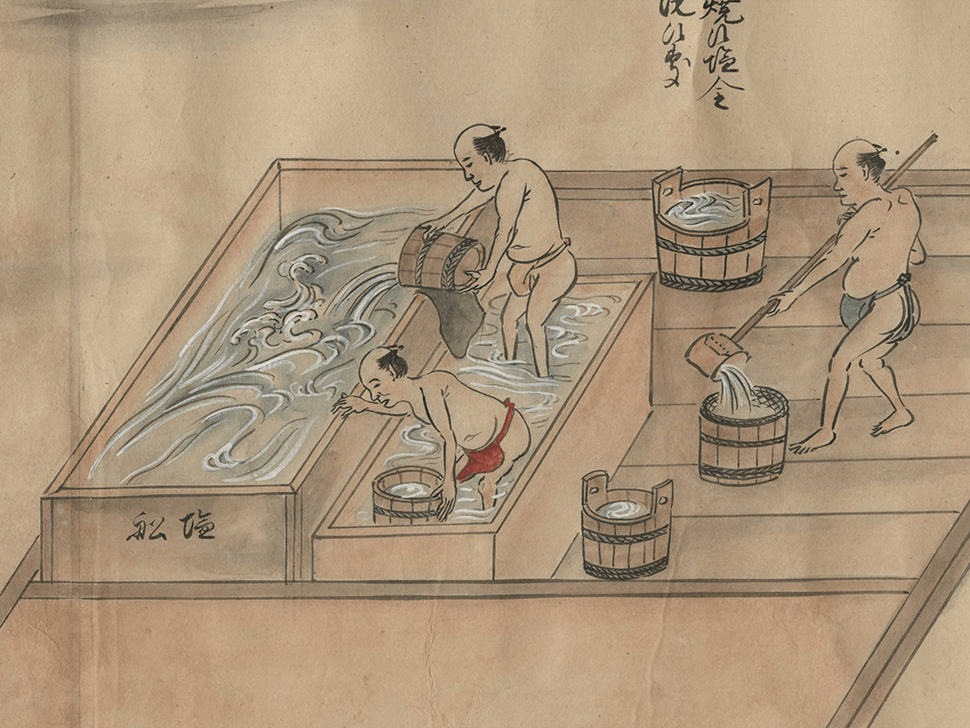

07.Place the heated lumps in water and break them apart. The silver chloride dissolves in water, leaving behind gold, which sinks at the bottom.

07.Place the heated lumps in water and break them apart. The silver chloride dissolves in water, leaving behind gold, which sinks at the bottom.

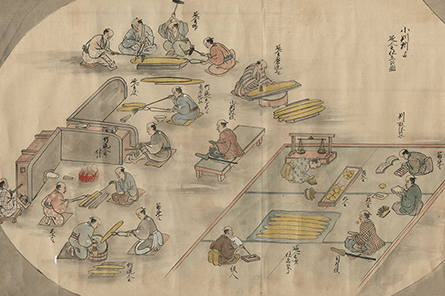

Minting koban gold coins

Aikawa not only produced gold and silver from ore but also minted koban coins. This was made possible by the isolated geography of the island and the magistrate’s office’s centralized management system. It is extremely rare throughout the world that everything from ore mining to minting koban coins was done at the same mining site. Koban coins were minted at the koban coin minting plant, located next to the magistrate’s office. First, gold is melted and hammered into plates, then cut with scissors into pieces as heavy as one koban coin. The pieces are then hammered into the shape of the koban coin, and a pattern called gozame (a pattern on a rush mat) is embossed on the coins. The coins are then subjected to the iroage (re-dyeing) process, in which they are coated with chemicals and heated to extract a better golden color before they are finished.

Sado’s koban coins were transported to Edo (present-day Tokyo) every year under strict guard. They were transported from Aikawa to Ogi and from Ogi to Izumozaki on the coast of present-day Niigata Prefecture by boat and further to Edo via the Hokkoku Kaido and Nakasendo routes.

(Picture scroll of gold mining on Sado)

[Collection of Aikawa Folk Museum]